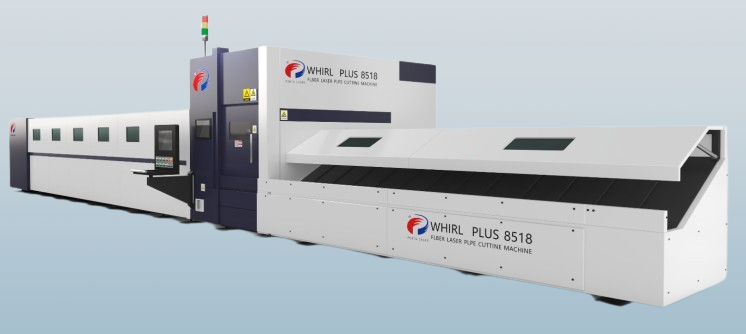

WHRIL PLUS

WHIRL PLUS pipe laser cutting machine is mainly used for processing round tube, square tube, oval tube and other kinds of special shaped products. More options for designers, the WHIRL-PLUS cuts tubes and profiles with great precision. This, in turn, enables the production of products of the highest quality and perceived value, for single-piece or series production, WHIRL-PLUS Tube Laser cutting guarantees maximum flexibility for the designer, this is a great advantage for manufacturers of Tube Laser components. WHIRL PLUS pipe laser cutting machine is mainly used for processing round tube, square tube, oval tube and other kinds of special shaped products. More options for designers, the WHIRL-PLUS cuts tubes and profiles with great precision. This, in turn, enables the production of products of the highest quality and perceived value, for single-piece or series production, WHIRL-PLUS Tube Laser cutting guarantees maximum flexibility for the designer, this is a great advantage for manufacturers of Tube Laser components. The bevel cutting option enables high-quality bevel cuts of up to 45°, the possibilities offered by WHIRL-PLUS Tube Laser cutting technology, mechanical engineers can replace or optimize sheet metal designs.

Tube Laser

- Optimum cutting result, Excellent process reliability and Increased flexibility

- Available in Laser Powers 1 – 4 kW laser source

- IPG/Raycus Laser Source

- RayTool Auto Focus Cutting Head

- Cut circular tube, square tube and other kinds of special shaped products.

- Automatic clamping and centering

- High-quality bevel cuts of up to 45° - Optional

- Automation compatible - Optional

- Available in 7010, 8518, 10018

- All India after Sales support

Main Parameters

| Sl. No | Specifications | Modal |

|---|---|---|

| 1. | Pipe Size | WHIRL PLUS 7010 ||7500 mm, WHIRL PLUS 8518 || 8500 mm, WHIRL PLUS 10018 || 10000 mm, WHIRL PLUS BV8518 || 8500 mm |

| 2. | Straight axis re-positioning accuracy | ± 0.03 mm/m |

| 3. | Rotation axis re-positioning accuracy | ± 0.02 mm/m |

| 4. | Rotation axis maximum speed | 120 m/min |

| 5. | X Travel | 7500 mm | 8500 mm | 10000 mm |

| 7. | Y Travel | 700 mm | 560 mm |

| 6. | Z Travel | 265 mm | 300 mm |

| 8. | Pipe Size | 20 - 180 mm | 20 - 180 mm | 60 - 220 mm |

| 9. | Laser Power Options | 1 kW - 4 kW |

| 10. | Laser Source Options | IPG / Raycus |